Bridge over troubled water

The Problem

Constraints:

- Reduce the number of popsicle sticks(ie. cost)

- Must fit within 22"x6" frame

Considerations:

- Sticks are not uniform

Design a truss which can support

200lb using only:

- popsicle sticks

- wooden gusset plates

- wood glue

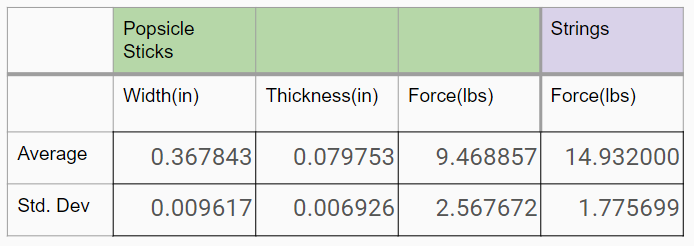

Statistical Analysis of Data & Calculations for Structural Safety

Popsicle stick average force: 9.469 lb

Popsicle stick standard deviation: 2.56 lb

b = 0.368 in

d = 0.07 in

M = PL/4 = (9.469 lbs * 2.56 in)/4 = 6.06 lb in

S = bd^2/ 6 = (0.368 * 0.07^2)/6 in^3 = 0.000301

Mstddev = PL/4 = (2.56 lbs * 2.56 in)/4 = 1.638 in

Sstddev = bd^2/6 = 0.000301

Bending stress = M/S = 20164 psi

20164 psi *bd = 519.429 lb (max bar force)

Bending stress stddev = 544 psi

544 psi * bd = 14.01 lb

Force average: 519.429lb

Force standard deviation: 14.01 lb

To have an error less than 5%:

Area under standard normal curve fromZ = -1.7

Z = (x - average)/(standard deviation)

x = 495.612 lb=max bar force

Material testing data summary

The solution

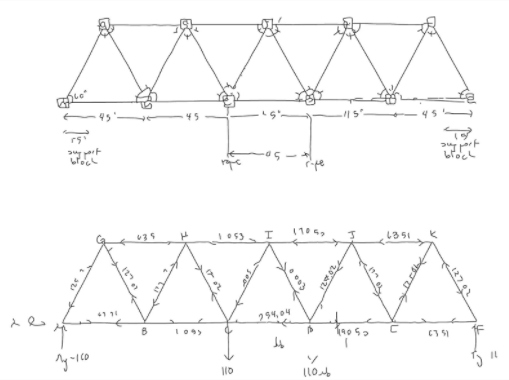

Designs considered

- Howe Truss with 6 splices and 12 joints

- 157.6"

- Warren Truss with no splices and 11 joints

- 118.5"

- Variation on Warren Truss with no splices

- 88.65"

- King Post Truss with 8 splices and 4 joints

- 52.62"

Warren Truss with no splices

2nd smallest bar length

All bar forces were safely under the 5% fail rate

Required no splices(less room for human error)

Easiest to construct without errors

Outcome:

Our truss, once built, was able to support Professor Kelvin’s weight as he walked the plank up until he was three feet away. When Kelvin was around four feet away our truss started creaking. At three feet away, the truss broke. It broke on the top middle joint due to compression forces.

Although we chose this design because of its simplicity in construction, we ended up being a little to relaxed and found our truss to be slightly too long to fit. It was remedied the day of testing by sanding off the ends.